- Automation in manufacturing streamlines processes, boosts productivity, reduces errors, and cuts operational costs.

- Digitization accelerates production pace, enhances inventory and supply chain management, and improves customer relationship management.

- The Internet of Things (IoT) can revolutionize manufacturing by providing data-driven insights for improving processes.

- Embracing cloud technology allows businesses easy, secure access to critical data for quicker decision-making.

- Prioritizing network security is crucial in digital operations to protect sensitive data and maintain trust.

The manufacturing industry has come a long way from its early days. With technological advancements, it has become easier to manufacture goods faster and with minimal physical labor. Technology has played an instrumental role in driving innovation in this industry. It has enabled businesses to transform their operations with automation, artificial intelligence, and the Internet of Things (IoT). This blog will look at the best tips for leveraging technology in your manufacturing business.

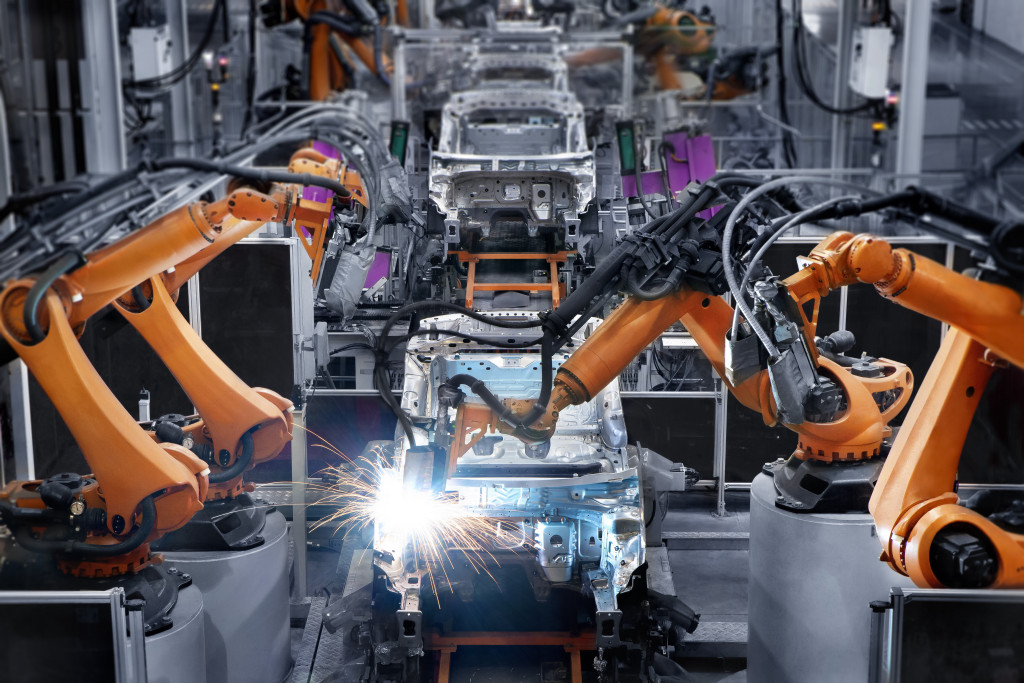

Invest in Automation

Automation is vital in streamlining manufacturing processes, increasing productivity, and reducing errors. By automating tasks that would otherwise require manual labor, businesses can reduce their reliance on human resources and reduce operational costs. Every aspect of the manufacturing process can be automated, from assembly to quality control. With the right software and machinery, businesses can achieve faster production rates without compromising on quality.

Some manufacturing automation examples include robotic arms for assembly and packaging, automated conveyor belts for material handling, machine learning algorithms for predictive maintenance, and computer-aided design (CAD) software for product design. Investing in automation may come with a high upfront cost, but it can result in significant long-term savings and increased efficiency.

Leverage Digitization

Digitization refers to the conversion of information from analog to digital form. It includes the conversion of paper-based processes to digital workflows, which can significantly accelerate the pace of manufacturing. Digitization can help increase speed, reduce errors, provide transparency, and improve the overall efficiency of the manufacturing process. There can also be other applications, such as the following:

Inventory Management

With digitization, businesses can easily track and manage inventory levels in real time. This ensures that there is always the right amount of inventory available, preventing stockouts and excess inventory. Businesses can streamline their inventory management processes by leveraging technology like RFID tags and barcodes.

Digital Marketing

Digital marketing for manufacturing industry operations allows businesses to reach a wider audience and generate leads through various online channels. With the right digital marketing strategy, manufacturers can showcase their products and services, engage with potential partners, and increase brand awareness. They can also use data analytics to track the success of their marketing efforts and make data-driven decisions.

Customer Relationship Management (CRM)

With digitization, it is easier for manufacturing businesses to keep track of customer interactions and maintain relationships with clients. CRM software can help businesses manage customer data, track sales and marketing efforts, and provide better customer service. By having a centralized customer information database, manufacturers can improve their communication with customers and tailor their products and services to meet their needs.

Supply Chain Management

Digitization can also improve supply chain management by providing real-time inventory levels, production processes, and shipment data. This allows manufacturers to make informed decisions about purchasing, production scheduling, and logistics. With digitized supply chain processes, businesses can reduce lead times, improve delivery accuracy, and address potential issues more efficiently.

Utilize IoT

IoT is the future of manufacturing, and it is already making a significant impact. The ability to connect devices and gather data from them has revolutionized the industry. With IoT, businesses can track the movement of products throughout the supply chain, monitor machinery performance, and even enable smart factories. But it’s not just about collecting data; it’s about using it to make informed decisions and improve processes. IoT can help manufacturers achieve significant cost savings and increase efficiency if utilized correctly.

Embrace the Cloud

The cloud has revolutionized the way businesses store and access data. With the cloud, companies can access data from anywhere at any time, and the data can be stored securely. This makes it easier for employees to access the information they need to perform their jobs effectively, whether at the plant or working remotely. Business-critical data, such as equipment performance, inventory levels, and machine status, are easily accessible, enabling quick decision-making.

Prioritize Network Security

As businesses increasingly transition to digital operations, they need to ensure the security of their networks. This involves implementing secure hardware and software infrastructure of their networks to prevent unauthorized access by cyber attacks. Regular backup, automated updates, and employee security awareness training are vital. Manufacturing companies store sensitive data about the business, its partners, and its customers. Any security breaches can result in the loss of trust from these parties and huge financial implications.

Leveraging technology in manufacturing is no longer optional but necessary to keep up in an evolving and demanding industry. By embracing automation, the Internet of Things, digitization, the cloud, and prioritizing network security, businesses can stay at the forefront of innovation and improve their bottom line. With the right technology, companies can improve their processes and working environments and scale their operations. The best time to start leveraging technology is now.