Industrial companies should take measures to ensure the safety of their workers and maintain a safe production line. These include implementing safety procedures and protocols, training workers on safely operating machinery, and ensuring that workers get adequately equipped with the necessary safety gear. Industrial companies should also periodically inspect their production lines to identify and address any potential safety hazards.

Here are some of the ways you can make your production line a safer place to work and manufacture products:

Update and Enforce Health and Safety Guidelines

Ensure that your company’s health and safety guidelines are updated and enforce them on all your workers. Don’t forget to review the policies periodically to ensure they’re still relevant to the operations of your facilities. Enforce the guidelines by incentivizing workers to follow them or educate them on the dangers of disobeying them.

Health and safety guidelines are your first line of defense against accidents and health hazards in the production line. By making sure that your workers know these guidelines, you can help create a safer environment for everyone.

Invest in Safety Training

Ensure that your workers get appropriately trained on operating machinery and handling materials safely. Safety training should be ongoing and not just a one-time event. It would help if you also had different safety training for different types of hazards. For example, if you have a production line that uses chemicals, you should provide chemical safety training to your workers.

Investing in safety training shows your employees that you care about their well-being, and it helps reduce the number of accidents in the workplace. It also helps improve productivity as workers feel more confident when they know how to perform their tasks safely.

Delegate A Safety Team or Safety Officers

Appoint a team of safety officers or delegates to monitor the production line for any potential hazards. These safety officers should have the authority to stop the production line if they identify a threat. They should also get trained on how to handle different types of emergencies.

Having a designated safety team can ensure that someone is always looking out for potential hazards. These can help reduce the chances of an accident happening in your production line.

Supply Safety Gear

Workers should have access to the necessary safety gear, such as gloves, goggles, and earplugs. They should also know how to use this gear properly. Ensure that the safety gear is readily available and that workers know where to find it.

Giving workers the necessary safety gear helps protect them from accidents and injuries. It also makes them feel more confident when performing their tasks, improving productivity.

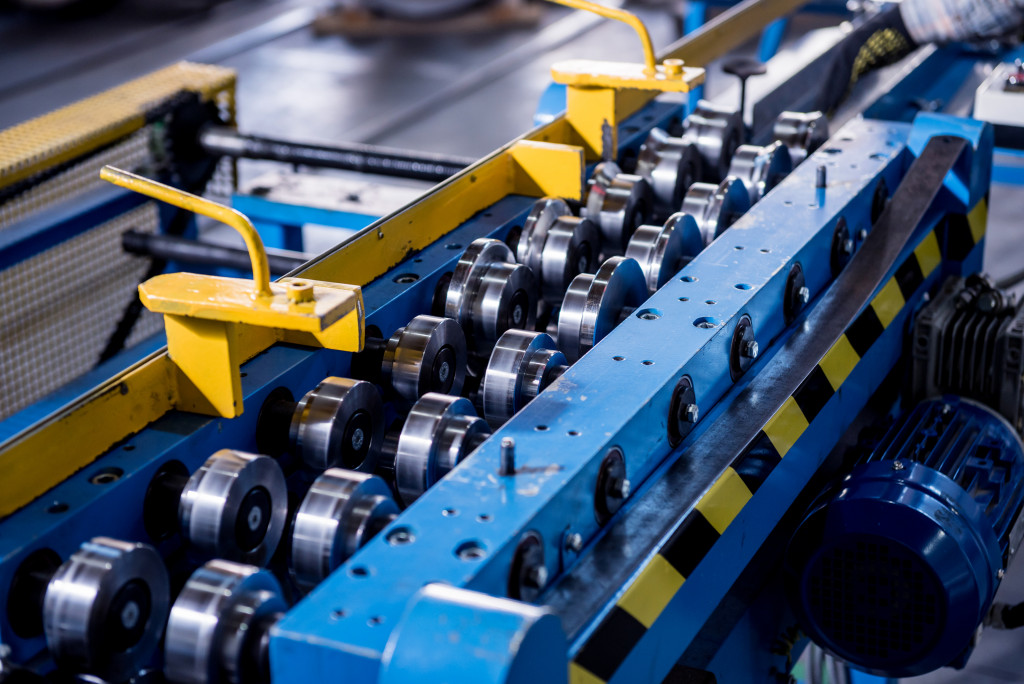

Update Your Machines and Equipment

Ensure that your machines and equipment are up-to-date and in good working condition. Periodically inspect them for potential hazards and address these hazards immediately. Also, consider investing in safety features such as emergency stop buttons and automated shut-off systems.

Updating your machines and equipment helps reduce the risk of accidents and improve productivity. Newer appliances and equipment are usually easier to operate and require less maintenance, meaning that workers can spend more time producing products instead of dealing with repairs.

Using newer machines and equipment also means they work much more straightforwardly and are safer. An excellent example of this is in more modern valve mechanisms. Valves that use pneumatic actuators are safer than traditional rack and pinion actuators. That’s because pneumatic actuators convert compressed air into usable energy. These actuators only use air and electricity to function, making it a simple mechanism that doesn’t have many points of failure.

Safety Inspections

Make sure to conduct regular safety inspections of your facilities and production line. Only trained personnel should perform them since they know how to identify potential hazards. Once they identify these hazards, they should fix them immediately.

Regular safety inspections help ensure that your production line is safe for workers. It also helps identify potential hazards before they become a problem.

Enforcing these guidelines will create a safer environment for your workers and help reduce the number of accidents in the workplace.

Keep Things Organized

An organized production line is a safe production line. Having a tidy workspace helps workers identify potential hazards more quickly. It also allows them to move around the workplace more efficiently, reducing the chances of an accident.

A well-organized production line is also more productive since workers can quickly find what they need and don’t waste time looking for things.

Accidents can happen in any workplace, but you can help reduce the risk of accidents in your production line by following these safety guidelines. Implementing these tips will require effort, but it’s worth it to keep your workers safe and productive. Make sure to review and update your policies periodically to ensure they still meet the needs of your facilities. And most importantly, enforce these guidelines by incentivizing workers to follow them or educating them on the dangers of disobeying them.