Businesses need to keep up with an ever-evolving world if they want to succeed. And for many types of businesses, like those in the manufacturing industries, making technological upgrades might spell life and death for their employees. If your business has been running for a while, here are some reasons why you need to consider making upgrades to your business technology and where and how you can start.

Newer technologies are safer

There is no denying that new machines and even robotics are much safer than their more outdated and obsolete counterparts. Many smart machines have collision detection systems that can ensure they don’t collide with or hurt humans they work alongside, making them reliable teammates.

And with business owners and managers having the mandate to ensure a safe workplace environment for their employees according to the Occupational Safety and Health Act (OSHA) of 1970, upgrading to new machinery is exactly what factory owners might need to ensure their workers are protected from various occupational hazards.

Newer technologies make things more convenient

When you see your employees spending more time fixing certain computers or machines instead of doing actual work, that is a clear-cut sign that your factory’s technologies need updating. Do not underestimate just how slow-moving computers or faulty machinery can disrupt your employees’ levels of motivation, energy, productivity, workflow, and output.

One example of a new tech tool that can make your operations easier is an industrial computer or PC, which can manage a host of applications and features, including using the internet of things (IoT) for remote maintenance, enhanced security, wireless manageability, and others.

Newer technologies protect your data better

If your business involves the handling of sensitive data, such as your client’s information, your factory will benefit from newer PCs that can help keep your data more secure. Outdated technology or older computers puts your company at increased risk, not just for data loss or corruption but also for security breaches. Another reason is that older servers and PCs might lag and crash, which can only cost you more money and time in the long run.

New technologies can help reach your business’s goals

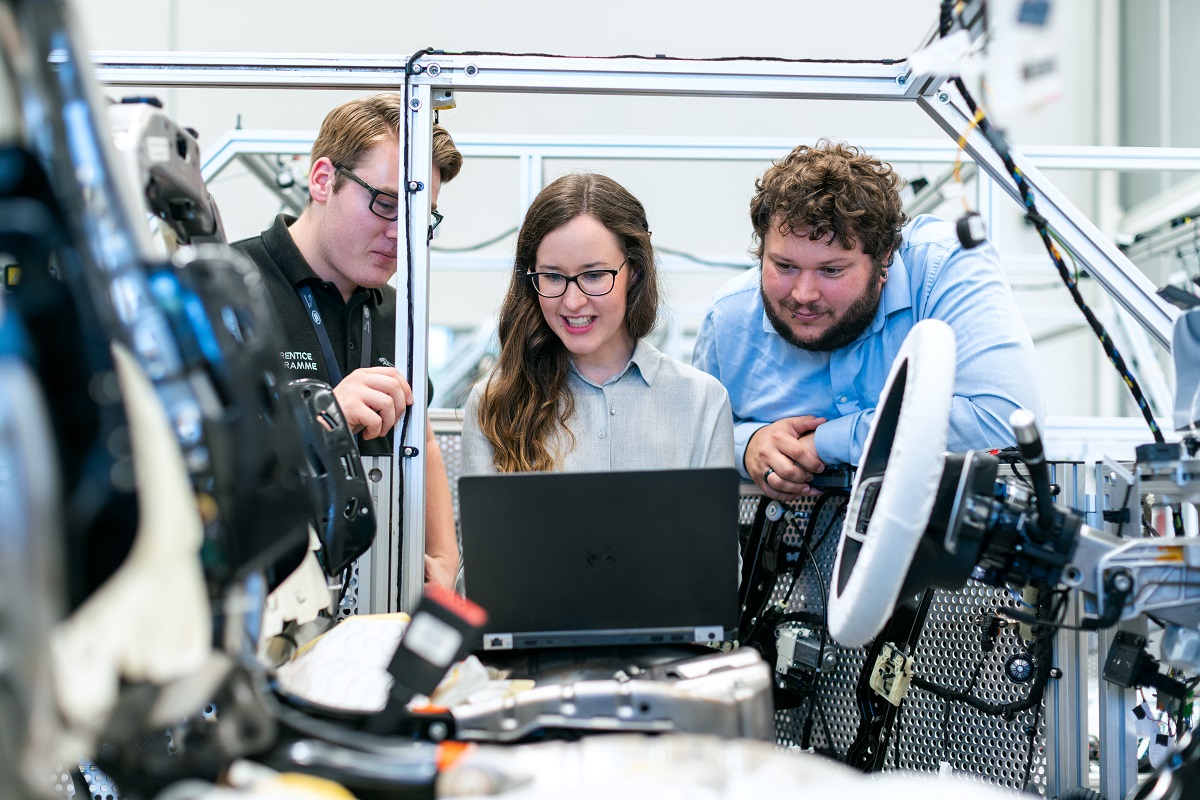

While automation has been utilized in manufacturing since the 1970s, technology has made great strides to improve upon that feature, and there are new advancements you can explore to ensure that your factory remains ahead of the curve and that you churn out the best products possible. While there are plenty of concerns about robotics and automation replacing human workers and how it could affect employment and the economy, the truth is so much more complex than that. Human workers and robots need to work hand-in-hand, and it is, by nature, a collaborative effort if owners want their business to increase in general efficiency.

Newer technologies help solve problems

If your factory has underlying problems, it might be because your operations are suffering due to the outdated technology you’re still using. Now might be the time to invest in new business technology and systems like better servers or hardware and more reliable and state-of-the-art machinery.

Tips for making technology upgrades

Here are some essential pointers for introducing new technological tools in your manufacturing company:

- Make sure your tech upgrades are aligned with your goals. Don’t just purchase a new machine just for the sake of it; make sure that every new investment will serve a purpose and that its present costs will offset any expenses you might have to shell out for in the long run.

- Explain to your employees the human benefits of automation. This is because many of them might see these new technologies as a threat to their tenure or job security. Tell them the advantages of these new tools, such as fewer injuries due to repetitive actions in the assembly line and an increased focus on more engaging and productive tasks.

- Gain a keen understanding of IoT. The idea of connected machinery, a key part of the Fourth Industrial Revolution, is crucial to the advantages of data collection in your factory. This technological trend is currently gaining ground in the manufacturing industry globally. If you want to keep pace, you would want to be one of the first to implement connected machinery.

The Bottom Line

If factories want to survive, they need to keep pace with new technologies and how these tools can help them operate better and more efficiently. And since the new normal will be more tech-driven, business owners need to utilize these new technologies before their competitors do.